Screeding levels, straight edges, screeding edges & co

SCREED LEVELS, STRAIGHT EDGES, SCREED EDGES & CO.

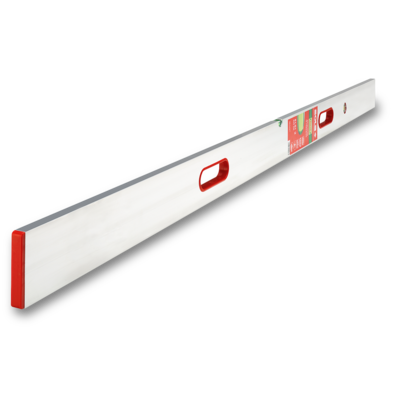

Barely any measuring tool has quite as many names as a screed level. Depending on its design and region, it might be called a straight edge, plasterer's float or screeding edge, along with a whole host of other names.

WHAT IS A SCREED LEVEL?

A screed level or edgeis a long, narrow tool used for a wide range of applications like peeling away large areas of screed or to plaster walls. It can also be used to inspect “straightening”, i.e. checking straight lines and surfaces.

Originally, screed edges were made from wood, which is why they were referred to as straight edges. Nowadays, they are made from high-strength aluminum profiles to guarantee optimum stability and durability. Their smooth profile makes aluminum screed edges and levels easy to clean.

The attached end caps also protect the profile from dirt. The end caps have a shock-absorbing effect and protect the profile from damage that would otherwise be sustained by impacts.

Generally speaking, screeding levels have a height of 100 mm, a width of 18 mm and a length varying between 1 and 6 m. Long screed levels are ideal for screeding large areas like floors in one go. Alternatively, shorter screeding edges are ideal for limited surface spaces.

Some models feature handles, which ensure a stable grip and prevent the tools from being dropped.

POTENTIAL APPLICATIONS FOR SCREED LEVELS

Screeding levels are used in a variety of trades. Floor layers use them to align tiles in a line, whereas pavers use them to level and even out leveling compounds like screed, chippings or sand. Bricklayers use screeding levels to check the height of decking, walls, stairs, etc. and carpenters use them as a guide for cutting wooden boards with a circular saw.

RED Clip mounting brackets can be used to connect a RED spirit level to a screeding level or edge, extending the list of potential applications for these tools. Surfaces can be leveled horizontally and precisely, inclines can be measured digitally, and facades can be measured vertically.

PLASTERER’S FLOATS A SPECIAL TYPE OF SCREEDING EDGE

Plasterer's floats are primarily used to finish surfaces when plastering walls. They can be used to smooth down both walls and floors. Plasterer's floats are generally made from aluminum to avoid deformation and are available in a trapezoidal or H-shape. Their narrow front edge makes them the ideal tool for working neatly along edges and in corners.

SCREEDING LEVELS. SCREEDING EDGES WITH VIALS.

In principle, a screeding level performs the same job as a screeding edge with the added bonus of a horizontal and/or vertical vial. As a result, the screeding edge can be used as a measuring tool like a spirit level. Screeding levels ensure precise vertical or horizontal alignment.

SOLA SCREEDING LEVELS AND EDGES TOP SOLA QUALITY ENSURED

Thanks to their high profile weight and thick walls, our durable SOLA screeding levels withstand any stresses they are exposed to on the construction site. quipped with the SOLA FOCUS vial and individually adjusted, they have a maximum measurement tolerance of 1.0 mm/m, allowing them to outperform all other quality screeding levels available.

PROFILE WEIGHT

The profiles of SOLA screeding levels weigh between 670 and 870 g, depending on the model, making them highly robust, durable and able to withstand any stresses they are exposed to. The thick wall thickness protects against extreme wear caused by pulling off plaster, fill material or gravel, or even if it is dropped on the construction site. This minimizes inaccuracies.

BREAK RESISTENT ACRYLIC TUBE VIALS

Since 2011 all SOLA quality spirit levels and screeding levels have been equipped with the patented FOCUS vial. Compared with standard ring vials our FOCUS vials show a considerably higher contrast, allowing for a better, faster and more accurate reading. This has been proved in tests by professional craftsmen throughout Europe. In addition to the unbeatable precision, the FOCUS vials are also distinguished by their resistance to breakage or deformation. Other quality features: The vial fluid is antistatic with a very good UV resistance. Patented SOLA ultrasonic welding ensures the vials are leakproof. SOLA FOCUS vials come with a 30-year leakproof guarantee.

INVERTED MEASUREMENT

Screeding levels SL2/SLG2 and SLGI2 are currently the only products on the market that allow measuring in the inverted position with a screeding level. This means that overhead applications, like suspending ceilings, are also possible.

THE PERFECT SCREEDING LEVEL FOR EVERY APPLICATION

No matter the length or the application the screeding level is used for, the vial is always at the user's eye level. This optimal positioning is what sets SOLA screeding levels apart. Selected screeding level modes come with two handles that provide additional comfort for the users when carrying out their work. Longer screeding levels, such as the SLG1, with vials on both sides of the level, allow accurate measuring also when working in pairs. Depending on the length of the level, the handles are located in varied positions, enabling the use by either one or two persons. In addition to the standard screeding levels family with a 10 cm profile height, SOLA also offers another product group, SLN, which is only 8 cm high. This is particularly useful for achieving higher (stand) stability.

QUALITY CONTROL

Each individual screeding level is tested and adjusted. SOLA screeding levels have a tolerance of 0.50 mm/m to 1.00 mm/m, depending on the model. They consequently outperform other quality screeding levels with a maximum measuring tolerance of 1.00 mm/m.